(01)Lubricator

Our original lubricating feature that earned an Award for Director-General of the Science and Technology Agency

Lubricator that was originally a component of railroad vehicle

The history of our lubricator goes all the way back to a production of flange lubricator for special-purpose vehicles by Fuji Flange Lubricator Co., Ltd., predecessor of FUTEC ORIGIN, where the flange lubricator was officially designated as a vehicle part of National Railways in 1959. In early railway system, lubrication was performed manually to reduce wear of wheel flange and rails. But there was a demand for auto lubricator for the purpose of more efficient operation and streamlining of maintenance work.

Therefore, the product with our original lubricating feature played a significant role in preventing wear of wheels that are the most important component of a railway vehicle.

While our product was used in steam trains, such as D51 and C58, at the beginning, and then in diesel and electric trains as time passes, it is being employed even now in some railway companies.

As the lubricator was used as a part of steam trains in the early days, we sometimes receive requests of reconstruction of a steam train with the same condition of that time.

Our original lubricator is used even now in some places, such as in SL operations in railway events held in Yamaguchi prefecture.

You may also find our original lubricator in some steam trains stored in your nearby park. So, please check it out.

-

Flange Lubricator (B-7000 model)

Flange Lubricator (B-7000 model)

-

SL at Shimbashi Station

SL at Shimbashi Station

-

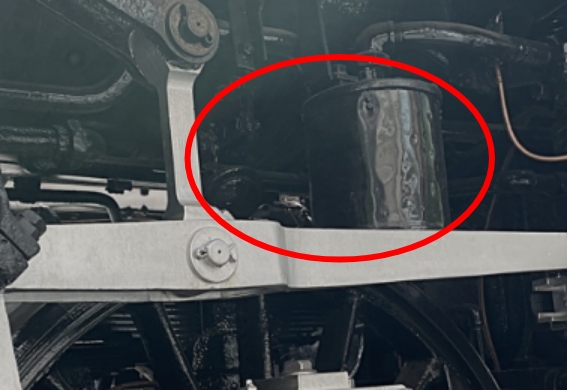

B7000 and tank are installed

B7000 and tank are installed

Characteristics of our lubricator

In around 1960, we developed successfully ultratrace high-performance FUJI MATIC pump, which ensures automatic and adequate lubrication without using neither power nor air source. It is used even now for our lubricating products as an original and inimitable core component.

It is known as FUJI MAGIC Pump in other countries, and widely used in places such as steel plants around the world.

-

FUJIMATIC PUMP

FUJIMATIC PUMP

-

Old catalogue

Old catalogue

Expanding our business to the areas other than railway vehicles

Initially, our lubricator played a major role as one of the components of railway vehicles. There was a trading company, which served as a sales contact to deliver our products to Ogura vehicle station in Kyushu, and also dealt with brake parts for large cranes used in steel plants. This trading company suggested that "this lubricator may be usable for cranes since cranes use rails and wheels with flange similarly to the railways". That was how we became to develop lubricator F type and then later RVF type.

These types of lubricators, which accommodate special needs, such as curved rails due to aging of a building, bumps made by ground sinking and twisted wheels caused by heavy load conveyance, are employed in shaft furnace and electric furnace across the country.

After that, we have developed some products that align with each customer's needs, including lubricator for large chain for step installation in escalator made by a major manufacturer, and anti-wear lubricator used for the rail side at a gate of a domed stadium.

Now, the inimitable and unique mechanism and excellent performance of our products have been recognized. We produce various types of equipment used not only for railways but also in steel plants that require a trace amount of lubrication, wheels and ropes for shipbuilding cranes, as well as gears and chains used in plants and machineries.

Our company tries to fulfill the diversified needs by producing highly reliable products that meet the necessary and sufficient conditions required for lubricator.

-

Rail-Type Lubricator/RVF Model

Rail-Type Lubricator/RVF Model

-

Centralized Lubrication System for Chains/EAL Model

Centralized Lubrication System for Chains/EAL Model

Productization of safety marker triggered by a challenge faced by a customer

In response to a request from one of our customers, a major steel plant that was using the lubricator, we developed a center marker. Replacing center marker stabilizer used to require a manual transportation to a crane crab dolly, which was a hard work because of the heavy weight.

In an effort of weight saving, we had developed with the customer a light-weight LED safe marker through a trial and error process by taking high-lift and measures against high-temperature environment and dust into consideration. A spot marker using halogen bulb as a light source was the predecessor of safe marker. Halogen bulb may remind you of a bulb in a flashlight used short while ago. In fact, the same halogen bulb was used in the spot marker, thus when the bulb burned out, the customer used to run to a store to buy a new halogen bulb.

The irradiation distance of the spot marker at the time was only as short as 3 meters. As the center marker began to be employed by shaft furnaces across the country with a demand for more compact and longer life of a product, we decided to develop safe marker.

The current safe marker has an irradiation distance of 20 meters at a maximum.

-

Spot Marker

Spot Marker

-

Center Marker

Center Marker

-

Safe Marker

Safe Marker