Safety marker

We achieved an improvement of

productivity and safety in the crane operation.

It requires considerable skills to move the crane hook promptly and accurately to center on top of load. An increased efficiency and manpower-saving are the keys to improve productivity at any manufacturing site.

The implementation of FUTEC ORIGIN's safety marker enables not only prompt and accurate positioning, but also to prevent damage on the load due to operation errors as well as angled hanging, all of which ultimately improves safety and saves labor of the ground workers.

Effect of implementing the safety marker

-

Improvement of work efficiency with better viewability

The safety marker not only enables prompt and accurate positioning of the hook, but also improves viewability of workers with clearer recognition of the work area and dangerous spots. This significantly improves the efficiency of crane operation. In addition, it has a profound effect in terms of technical support for unskilled crane operators.

-

Effective safety measures with improved viewability

With an improved viewability, the safety marker prevents damage on the load and angled hanging, reducing a risk of accident. It also decreases a risk of injury for workers allowing to achieve effective safety measures.

-

Prevention of damage on the load caused by operation error

Any damage on the expensive goods not only causes economic loss due to incurrence of repair/replacement cost and delayed delivery, but also leads to a loss of trust of customers. The improved viewability helps to mitigate damage risk and avoid a loss.

-

Manpower saving and cost reduction

With an improved viewability, operator is able to accurately recognize the work area and dangerous spots from a distance. This helps to eliminate ground workers (such as flag person) to save manpower. The human resources may be moved to other positions, leading to a cost reduction.

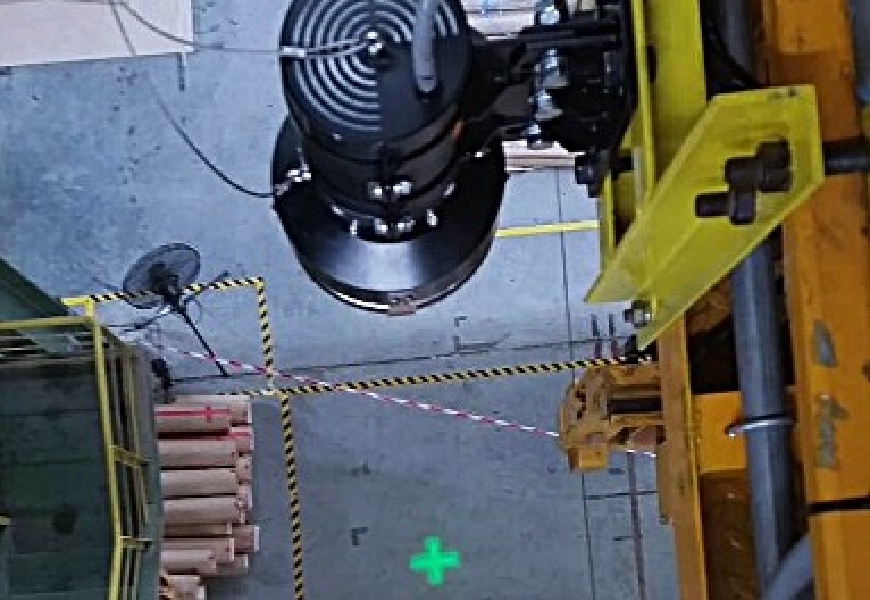

Usage Examples

The safety marker is usable on the shop floor in a variety of industries, including plants and warehouses.

-

Center mark of hoisting attachment

When hoisting scroll materials such as coil, the hoisting attachment must be exactly matched to the center of the hoisting object.

By visibly showing the center position to an operator, offset load can be prevented,

contributing to prevent accidents caused by load swing and unbalanced load. -

Judgment of length/dimension of long objects

The lengths of the pipes and steel bars can be judged during the transport without contact. Check the length by focusing the (linear) mark of the marker on both ends of the object.

-

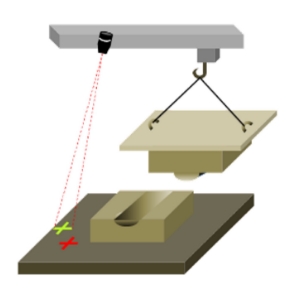

Positioning of press mold

The safety marker is used in the mold changeover process among other precise tasks of positioning upper and lower molds of the pressing machine.

By adjusting the position using the marker, it prevents mold damage. -

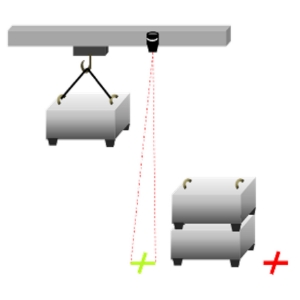

Confirmation of loading location

The safety marker may be used to confirm whether the object is correctly located at a designated place when loading or allocating the load or products.

-

Determination of height and position of the coil

The safety marker supports the centering and positioning when the coiled material are placed on the uncoiler.

Also, it prevents the material being distorted or damaged in the uncoiling movement. -

C-hook handling aid

When transporting the coil, during hoisting operation using C-hook, the safety marker provides guide to the operator as to appropriate grasping position, preventing cargo from shifting and damaging the facility due to wrong way of hanging.

*The safety marker can be used in situations other than the above. Please consult with us about your concern.

FUTEC ORIGIN's safety markers

(01) Type comparison

There are two types of product; one using LED and the other using mercury lamp.

Please select according to the use environment.

| Safety marker (LM-G type) | Center marker (CCM-type) | |

|---|---|---|

| Light source | LED | Mercury lamp |

| Irradiation distance(m) | 3~20m | 7~30m |

| Form | Integrated type | Discrete type (stabilizer) |

| Irradiation mark | Cross *As an option, other shapes are available. | Cross *As an option, other shapes are available. |

| Irradiation mark color | Green | Lemon yellow |

| Offered types | 4 types | 2 types |

| Power source voltage | AC single phase 90~220V (±10%), 50/60Hz | AC single phase 200/400V (±20%), 50/60Hz |

| Dimension | Smaller | Larger |

| Main Unit Weight(kg) | 4.1 ~6.3kg | 26 or 32kg |

(02) Product overview

"Safety marker", the industry-first small marker with LED light source

Characteristics of LM series

-

Use of LED light

High light intensity and high-viewability are achieved by adopting high-power LED.

With the power consumption as low as approx. 40w, this makes it possible to minimize the running cost. -

Compact size

It is small enough to be installed on small cranes such as hoist.

-

Long life

The lamp life is as long as 40,000 hours.

(*The value is an estimated life of lamp element, but not a product's guarantee time.) -

Select from 4 types

A user can select from 4 different types depending on the purpose and use conditions.

Exterior Appearance of Each Type

Projection mark

| Name | LM-G type-I | LM-G type-II | LM-G type-III | LM-G type-IV |

|---|---|---|---|---|

| Dimension(mm) | 250 × 100 × 100 | 300 × 110 × 110 | 300 × 160 × 160 | 540 × 210 × 210 |

| Weight(kg) | 4.1kg | 4.6kg | 5.1kg | 6.3kg |

| Irradiation distance(m) | 1~5m | 4~10m | 9~20m | |

*The type-III has the same lens focal length, element and pattern mask size as the type-II, but has larger lens diameter to enlarge the irradiated slits.

(03) Product specifications

| Input voltage (V) | AC90~AC220V (±10%) |

|---|---|

| Input frequency (Hz) | 50/60Hz |

| Power consumption (W) | Approx. 40w |

| Fuse | 250V 4A |

| Estimated life of lamp element (h) * | 40,000h |

| Light intensity adjusting mechanism | N/A |

| Cooling method | Forced fan air cooling |

| Use environment temperature (℃) | Minus 5 - 50 (with no freezing/condensation, no outdoor use) |

| Cable | Standard VCTF1.25sq×3C 5m (grounded, unprocessed on one side) |

| Light-source color | Green |

| Used lens | Fresnel lens |

*The value is an estimated life of lamp element, but not a product's guarantee time.

(02) Product overview

"Crab center marker", mercury lamp-type with high durability

Make the crane operation safer and more accurate with Crab center marker.

The Crab center marker is the only mercury lamp high-brightness projector in the industry that combines the original supervoltage mercury lamp and high precision optics technology. It can project bright and clear marks as far as max. 30m ahead (20m for S-type).

This marker enables accurate positioning of the crab and the hanging load. The operation used to require proficient skills, but now it can be smoothly performed by anybody. An operator ensures the positional relation between the bright mark projected on the ground and the hanging load at a glance, and operates the crab promptly and accurately.

(03) Product characteristics

- Clear projection with high bright level of 10,000 lux

- Clearly projects as far as max. 30m ahead

- Significantly reduces the workload on the crane operator

- Dramatically improves the work efficiency and safety

(04) Product specifications

CCM-S type

CCM-H type

Projector

| Name | CCM-S type | CCM-H type |

|---|---|---|

| Dimension(mm) | Main body 780×330×330 | Main body 900×330×330 |

| Weight(kg) | Main body 26kg | Main body 32kg |

| Projection distance(m) | 7m~17m | 17m~30m |

Stabilizer

| Operation power source | AC single phase 200/400V ±20% 50/60Hz (fixed) |

|---|---|

| For input power source 200V | No load 0.5A Load 2.5A |

| For input power source 400V | No load 0.3A Load 1.5A |

| Cooling method | Forced cooling |

| Dimension(mm) | 450×320×310 |

| Weight(kg) | 38kg |

(05) Product configuration

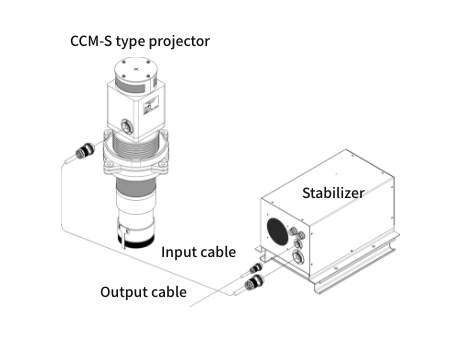

Stabilizer and projector's main body (Photos of the actual equipment)

CCM-S type projector configuration diagram

Projection mark