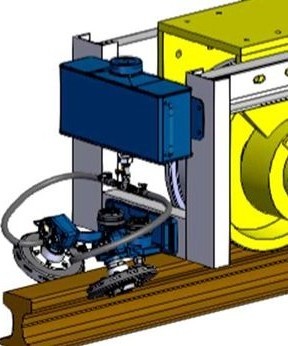

Wet typeLubricator

Rail lubricator/RVF-type

One unit of lubricator can reduce wear in two areas as the oil applied to the rail is transferred to the flange

Product Features

・The oil is transferred from the lubricated rail-side to the flange portion, protecting both rails and flange from friction.

・Without requiring electric or air source, flange is lubricated with a infinitesimal quantity of oil that is discharged only when the crane is in operation. It reduces flange wear and extends the wheel replacement interval (by 4-5 times for wheels or 2-3 times for rails).

・A built-in FUJIMATIC PUMP enables a stable, tiny amount of oil discharge.

・As it lubricates both sides of the rail simultaneously, fewer points of installation are necessary, making maintenance easier.

・Since the lubricating wheels are designed to swing horizontally, they don't miss the lubricating points even the crane sways from side to side while in operation.

Implementation Examples

Used for traveling wheels of overhead traveling cranes/jib cranes/gantry cranes at steel plants, shipyard and harbor.

| Other specifications | There are three products available depending on the amount of oil discharge (RVF 500/1000/1800) *Please make an inquiry about the difference of each product. |

|---|---|

| The number of installation | 2 sets of lubricator (body) and oil tank per crane |

| Contents | Lubricator (body), oil tank (5L, with T-joint), and hose (2000mm) x2 |

| Weight | Approx. 12kg |